- Products

- Market Solutions & Services

- Insight

- Tools & Resources

- About Nexans Australia

- Search

- Contact us

- Compare

- Sign in

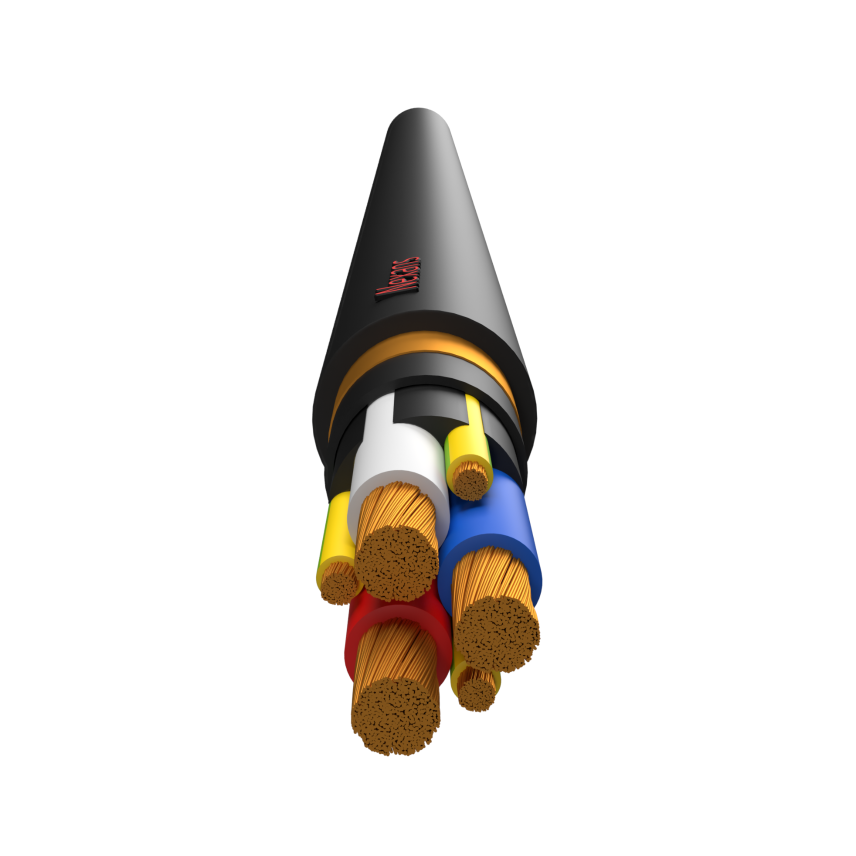

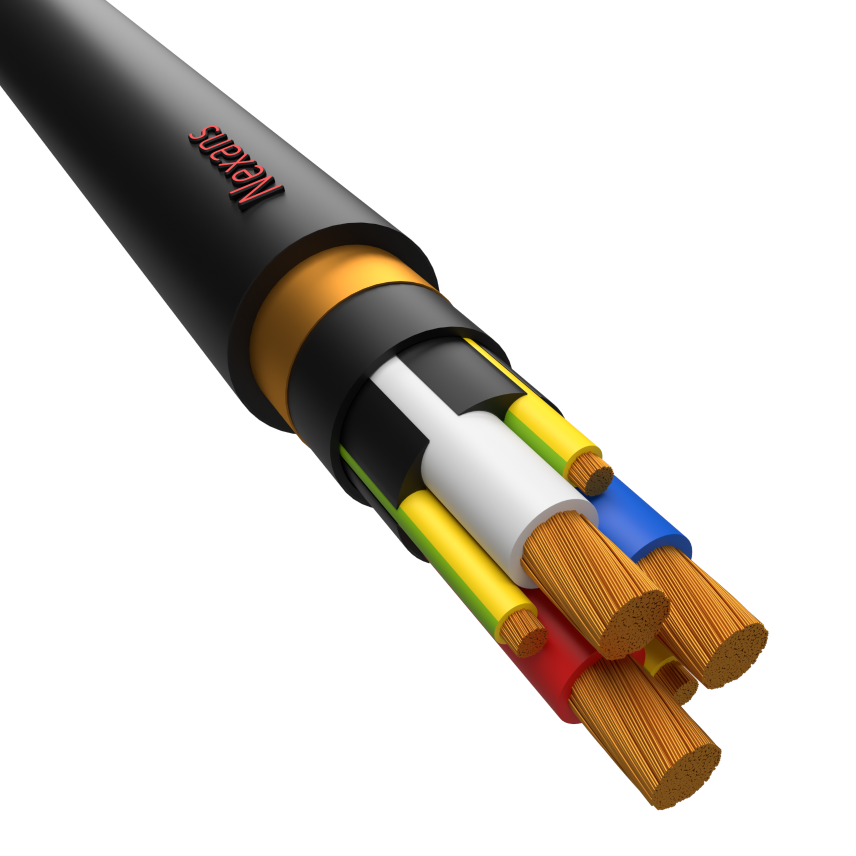

VAROLEX® VSD/EMC 3C+3E

VAROLEX® VSD/EMC 3C+3E

3C + 3E Copper Conductor, 0.6/1kV X-90 insulated, PVC bedded, copper tape screened, PVC sheathed to AS/NZS 5000.1, 90°C

Read more3X25mm2 + 3E Varolex Black

Nexans ref. FTDC17AA003CXRJ - Country ref. FTDC17AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 12 mm²

- Conductor cross-section: 25 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 2.8 kN

- Minimum Bend Radius - During Installation (under Tension): 420 mm

- Minimum Bend Radius - Installed: 280 mm

3x35mm2 + 3E Varolex Black

Nexans ref. FTDC18AA003CXRJ - Country ref. FTDC18AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 18 mm²

- Conductor cross-section: 35 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 3.13 kN

- Minimum Bend Radius - During Installation (under Tension): 470 mm

- Minimum Bend Radius - Installed: 315 mm

3x50mm2 + 3E Varolex Black

Nexans ref. FTDC19AA003CXRJ - Country ref. FTDC19AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 30 mm²

- Conductor cross-section: 50 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 3.49 kN

- Minimum Bend Radius - During Installation (under Tension): 525 mm

- Minimum Bend Radius - Installed: 350 mm

3x70mm2 + 3E Varolex Black

Nexans ref. FTDC20AA003CXRJ - Country ref. FTDC20AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 30 mm²

- Conductor cross-section: 70 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 3.88 kN

- Minimum Bend Radius - During Installation (under Tension): 580 mm

- Minimum Bend Radius - Installed: 390 mm

3x95mm2 + 3E Varolex Black

Nexans ref. FTDC22AA003CXRJ - Country ref. FTDC22AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 48 mm²

- Conductor cross-section: 95 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 4.43 kN

- Minimum Bend Radius - During Installation (under Tension): 665 mm

- Minimum Bend Radius - Installed: 445 mm

3X2.5mm2 + E Varolex Black

Nexans ref. FTDP07AA003CXRJ - Country ref. FTDP07AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 2.5 mm²

- Conductor cross-section: 2.5 mm²

- Number of earth cores: 1

- Maximum Pulling Tension: 0.5 kN

- Minimum Bend Radius - During Installation (under Tension): 265 mm

- Minimum Bend Radius - Installed: 175 mm

3X4mm2 + E Varolex Black

Nexans ref. FTDP09AA003CXRJ - Country ref. FTDP09AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 4.5 mm²

- Conductor cross-section: 4 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 0.8 kN

- Minimum Bend Radius - During Installation (under Tension): 305 mm

- Minimum Bend Radius - Installed: 205 mm

3X6mm2 + 3E Varolex Black

Nexans ref. FTDP11AA003CXRJ - Country ref. FTDP11AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 4.5 mm²

- Conductor cross-section: 6 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 1.3 kN

- Minimum Bend Radius - During Installation (under Tension): 320 mm

- Minimum Bend Radius - Installed: 215 mm

3X10mm2 + 3E Varolex Black

Nexans ref. FTDP13AA003CXRJ - Country ref. FTDP13AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 4.5 mm²

- Conductor cross-section: 10 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 2.1 kN

- Minimum Bend Radius - During Installation (under Tension): 335 mm

- Minimum Bend Radius - Installed: 225 mm

3X16mm2 + 3E Varolex Black

Nexans ref. FTDP15AA003CXRJ - Country ref. FTDP15AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 7.5 mm²

- Conductor cross-section: 16 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 2.54 kN

- Minimum Bend Radius - During Installation (under Tension): 380 mm

- Minimum Bend Radius - Installed: 255 mm

3X120mm2 + 3E Varolex Black

Nexans ref. FTDP23AA003CXRJ - Country ref. FTDP23AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 48 mm²

- Conductor cross-section: 120 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 5.23 kN

- Minimum Bend Radius - During Installation (under Tension): 785 mm

- Minimum Bend Radius - Installed: 525 mm

3X150mm2 + 3E Varolex Black

Nexans ref. FTDP24AA003CXRJ - Country ref. FTDP24AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 75 mm²

- Conductor cross-section: 150 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 5.57 kN

- Minimum Bend Radius - During Installation (under Tension): 835 mm

- Minimum Bend Radius - Installed: 555 mm

3X185mm2 + 3E Varolex Black

Nexans ref. FTDP25AA003CXRJ - Country ref. FTDP25AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 75 mm²

- Conductor cross-section: 185 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 6.14 kN

- Minimum Bend Radius - During Installation (under Tension): 920 mm

- Minimum Bend Radius - Installed: 615 mm

3X240mm2 + 3E Varolex Black

Nexans ref. FTDP26AA003CXRJ - Country ref. FTDP26AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 105 mm²

- Conductor cross-section: 240 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 6.83 kN

- Minimum Bend Radius - During Installation (under Tension): 1025 mm

- Minimum Bend Radius - Installed: 685 mm

3X300mm2 + 3E Varolex Black

Nexans ref. FTDP27AA003CXRJ - Country ref. FTDP27AA003CXRJ

- Packaging: Cut to length (m)

- Combined earth size section: 150 mm²

- Conductor cross-section: 300 mm²

- Number of earth cores: 3

- Maximum Pulling Tension: 7.69 kN

- Minimum Bend Radius - During Installation (under Tension): 1155 mm

- Minimum Bend Radius - Installed: 770 mm

Description

Description

Standards

-

ProductAS/NZS 1125; AS/NZS 5000.1

- Intended for fixed variable speed drive applications

- 0.6/1kV X-90 insulated,

- 3 core+3 earths,

- PVC bedded,

- Copper tape screened,

- PVC sheathed to AS/NZS 5000.1,

- Stranded Copper conductors, 90°C

*For 2.5 mm², split earth not feasible, therefore a single earth conductor is utilised.

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Current carrying capacities three phase (in Amps)

Insulation type: X-90, X-HF-90, R-EP-90, R-CPE-90, R-HF-90 OR R-CSP-90

Maximum conductor temperature: 90°C

Reference ambient temperature: 40°C IN AIR, 25°C IN GROUND

| Conductor cross-section |

|

|

|

|

|

|

|

|

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm² | Cu | Al | Cu | Al | Cu | Al | Cu | Al | Cu | Al | Cu | Al | Cu | Al | Cu | Al | Cu | Al |

| 1.0 | 16 | 0 | 14 | 0 | 12 | 0 | 7 | 0 | 13 | 0 | 10 | 0 | 6 | 0 | 22 | 0 | 16 | 0 |

| 1.5 | 20 | 0 | 19 | 0 | 15 | 0 | 9 | 0 | 16 | 0 | 13 | 0 | 8 | 0 | 28 | 0 | 20 | 0 |

| 2.5 | 28 | 0 | 26 | 0 | 21 | 0 | 13 | 0 | 24 | 0 | 19 | 0 | 12 | 0 | 39 | 0 | 29 | 0 |

| 4.0 | 38 | 0 | 35 | 0 | 28 | 0 | 18 | 0 | 30 | 0 | 24 | 0 | 15 | 0 | 51 | 0 | 37 | 0 |

| 6.0 | 48 | 0 | 45 | 0 | 36 | 0 | 22 | 0 | 38 | 0 | 30 | 0 | 19 | 0 | 63 | 0 | 46 | 0 |

| 10.0 | 66 | 0 | 62 | 0 | 49 | 0 | 31 | 0 | 53 | 0 | 42 | 0 | 26 | 0 | 85 | 0 | 63 | 0 |

| 16.0 | 88 | 68 | 83 | 64 | 66 | 51 | 41 | 32 | 68 | 53 | 55 | 42 | 34 | 26 | 110 | 85 | 81 | 63 |

| 25.0 | 119 | 93 | 111 | 84 | 89 | 69 | 56 | 43 | 91 | 71 | 73 | 57 | 46 | 36 | 143 | 111 | 107 | 83 |

| 35.0 | 147 | 114 | 137 | 106 | 110 | 85 | 69 | 53 | 114 | 88 | 91 | 71 | 57 | 44 | 172 | 133 | 130 | 101 |

| 50.0 | 180 | 140 | 168 | 10 | 134 | 104 | 0 | 0 | 136 | 105 | 108 | 84 | 0 | 0 | 204 | 159 | 155 | 120 |

| 70.0 | 229 | 178 | 213 | 165 | 170 | 132 | 0 | 0 | 173 | 134 | 138 | 107 | 0 | 0 | 251 | 195 | 193 | 150 |

| 95.0 | 283 | 220 | 263 | 204 | 210 | 163 | 0 | 0 | 209 | 162 | 167 | 129 | 0 | 0 | 302 | 234 | 233 | 181 |

| 120.0 | 330 | 256 | 306 | 238 | 245 | 190 | 0 | 0 | 246 | 192 | 197 | 153 | 0 | 0 | 344 | 268 | 270 | 210 |

| 150.0 | 377 | 293 | 350 | 272 | 280 | 217 | 0 | 0 | 277 | 216 | 222 | 172 | 0 | 0 | 385 | 299 | 304 | 236 |

| 185.0 | 436 | 340 | 404 | 315 | 323 | 252 | 0 | 0 | 322 | 251 | 257 | 201 | 0 | 0 | 435 | 340 | 348 | 272 |

| 240.0 | 517 | 405 | 479 | 375 | 383 | 300 | 0 | 0 | 386 | 303 | 309 | 242 | 0 | 0 | 504 | 395 | 411 | 322 |

| 300.0 | 594 | 467 | 549 | 432 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 567 | 446 | 463 | 365 |

| 400.0 | 685 | 545 | 632 | 504 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 640 | 510 | 524 | 417 |

| 500.0 | 779 | 629 | 718 | 579 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 714 | 577 | 601 | 485 |

|

Unenclosed spaced |

|

Unenclosed touching |

|

Unenclosed and partially surrounded by thermal insulation |

|

Unenclosed and completely surrounded by thermal insulation |

|

Enclosed conduit in air |

|

Enclosed, partially surrounded by thermal insulation |

|

Enclosed, completely surrounded by thermal insulation |

|

Buried direct |

|

Underground ducts A |

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania

.png/jcr:content/Untitled%20design%20(8).jpg)